Note: For your convenience, step-by-step build videos and recommended products are linked at the bottom of this post so you can follow along or shop as you go.

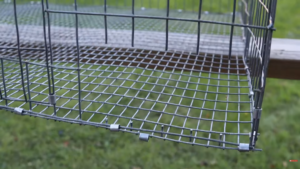

How to Build Durable Rabbit Cages for a Healthy, Professional Rabbitry

Hi everybody, Bobby from the Rabbitry Center here. Today I want to walk you through exactly how we build our rabbit cages, why we chose cages over colony raising, and what materials actually last long-term. This method has worked for us for years and supports both animal welfare and a professional rabbitry operation.

If you’re raising rabbits for meat, breeding, or sales, this guide will help you build cages that are durable, hygienic, and easy to manage.

Why We Use Cages Instead of Colony Raising

When we first started, our goal was simple: meat production. But one thing led to another, and soon we were selling rabbits, taking reservations, and helping other families start their own rabbit meat operations.

We chose cages because they allow us to:

Inspect every rabbit and litter easily

Control breeding accurately

Monitor health before a rabbit is sold

Get the most productivity out of our breeding does

When you’re selling rabbits or taking deposits, the last thing you want is to discover a health issue in an animal that’s already spoken for. Cages make consistent care possible.

Choosing the Right Cage Wire (This Matters)

Not all rabbit cages are created equal.

Avoid Painted Pet Store Cages

Many store-bought cages are made with painted wire that’s baked on, not galvanized. These cages:

Use Galvanized Wire Instead

Galvanized cage wire is designed for outdoor use and can last decades. It costs more upfront, but the difference is night and day. You truly get what you pay for.

Proper Wire Size and Gauge for Rabbit Cages

Side and Top Panels

Wire size: 1 inch x 2 inch

Strong, breathable, and easy to work with

Cage Floor (Very Important)

The cage floor supports your rabbit’s weight, so wire thickness matters.

Lower gauge numbers mean thicker wire. Thicker floors help prevent sagging and sore hocks.

Cage floors get a bad reputation mostly because of overfeeding. Keep your rabbits at a healthy weight and sore hocks are rarely an issue.

Cage Floor Bottom: A Critical Choice (Read This Carefully)

The cage floor bottom is one of the most important decisions you’ll make when building rabbit cages—and it’s often overlooked.

Unlike most of the cage wire we use (which you can find on Amazon using our links), cage floor wire deserves extra attention, especially if:

You raise rabbits larger than small breeds

You use nesting boxes or hide boxes

You want cages that stay flat and strong long-term

Recommended Cage Floor Specifications

Wire size: ½ inch x 1 inch

Gauge: 14 gauge (14G) — highly recommended

While 16G flooring can work, 14G is strong enough to carry the extra load from:

Thinner wire will eventually bow or sag, which can cause discomfort, poor drainage, and structural issues. A flat, rigid floor protects your rabbits and extends the life of your cages.

Where to Buy True 14G Cage Floor Wire

We recommend Klubertanz for 14G cage wire. They do things the old-fashioned way and focus on quality and customer service.

14G ½” x 1″ cage floor

Rolls or precut pieces

Knowledgeable support to help you order the right material

How to Place an Order with Klubertanz

Phone (preferred): 1-800-237-3899

They prefer phone orders so they can provide accurate shipping estimates and product guidance.Email: klubertanz@ticon.net

Fax: 608-884-7509

Mail: Order using the printed catalog order form

A free paper catalog is available upon request. [Online Catalog]

If you’re serious about building cages that last and supporting the health of your rabbits, this is one place not to cut corners.

Cage Dimensions We Use:

30″ wide x 30″ deep x 18″ tall breeder cage

- 36″ wide x 30″ deep x 18″ tall grow-out cage

This size works well for breeding does, grow-outs, and general housing.

Step 1: Cut the Side Panels

You can cut on:

A picnic table

A deck

A sidewalk

Let the cut line hang over the edge so your cutters don’t bind.

Step 2: Cut the Top Panel

Trim it down to 30 x 30 inches by cutting off 6 inches if your not making a grow-out cage

This gives you a perfectly square top.

Step 3: Cut the Floor Panel

Most rolls come 30 inches wide, so you only need one cut.

Step 4: Assemble the Cage

Attach the remaining two panels

Form a box shape

Secure seams with J-clips (about 3 per seam)

Pro Tip

When attaching the top and bottom:

Start in a corner, not the middle

Work your way across evenly

This prevents the cage from pulling out of square.

Step 5: Cut and Install the Door

We use hide boxes that are 11.5 inches square, so we cut:

Door Rules

The door must be larger than the opening

It needs overlap on all sides so rabbits can’t push through

If the wire doesn’t line up perfectly, clamp it and make it work. These cages are very forgiving.

Step 6: Feeder and Water Openings

Feeder Opening

We use smaller J-feeders

Cut out 5 wire spaces

Water Bowl System

This prevents:

Kits pulling water bowls out

Kits jumping out of the cage

Mistakes Happen — Here’s How to Fix Them

If you cut the wrong section (it happens):

These small patch jobs are strong and perfectly safe. We’ve fixed plenty over the years.

Final Thoughts on Rabbit Cage Building

You can build cages by bending the sides down, which is faster and easier on tools. However, cutting each panel separately:

It may cost you a few extra cutter wheels, but the end result is worth it.

If you’re serious about raising healthy rabbits and running a clean, efficient rabbitry, this cage design will serve you well for years.

Thanks for reading, and we’ll see you in the next guide.

AMAZON LINKS FOR PRODUCTS

1/2″x 1″ 14 gauge for bottom cage wire- [Online Catalog]

1″ x 2″ Cage wire for sides- https://amzn.to/329GWVT

1″x 2″x 36″ Top Cage wire- https://amzn.to/4qg3XjY

J-clips only- https://amzn.to/38anYzB

Pliers only- https://amzn.to/2I7eHOi

J-clips & pliers- https://amzn.to/3bWUcSi

Door latch- https://amzn.to/2wxJmlm

2×4 Clamps https://amzn.to/2PA9Vgm

Grinder- https://amzn.to/2uZgwty

Cutter Wheels- https://amzn.to/4jAKXKr

Battery- https://amzn.to/3afPjll

2Watch the Full Rabbit Cage Build Videos (Both Methods Explained)

This blog post is built directly from two real cage build videos we filmed in the rabbitry. Together, they show both ways we build cages and explain why certain material choices matter depending on your setup.

Watching both videos will give you the full picture—from wire selection and layout to fast assembly and finishing details—and help you avoid common mistakes like sagging floors and poorly sized doors.

🎥 Video 1: Traditional Panel-by-Panel Rabbit Cage Build (Detailed Method)

This first video is the foundation for this blog post. It shows the slower, more deliberate method where each panel is cut separately before assembly.

👉 Build A Rabbit Cage In 30 Minutes Or Less

This method takes a little more time and uses more cutter wheels, but it produces an extremely solid, long-lasting cage.

🎥 Video 2: Faster Rabbit Cage Build Using Fold-Up Sides (Efficient Method)

The second video shows a faster build style that many people prefer once they’re comfortable working with cage wire.

This build method is ideal if you want to produce multiple cages efficiently while still maintaining strength and proper dimensions.

Why We Show Both Builds

Both cage build styles work. The key is understanding:

Wire quality and gauge matter more than speed

Cage floor bottoms must be strong enough to stay flat under load

Door size and placement affect daily usability

By watching both videos alongside this guide, you’ll be able to choose the method that fits your skill level, tools, and rabbitry goals—and build cages that stay solid for years.

Thanks for reading, and we’ll see you in the next guide.